Selecting the proper engraving machine is among the most important decisions for the flexographic and gravure printing companies. The efficiency of engraving machines has a direct relation to the quality of prints and the time taken in the printing process. In this printing plate making, it involves creating plates that are used to transfer ink onto paper or other surfaces during printing. The information provided below will help in choosing the right engraving machine pegged on the plate size and the number of prints to be made.

Understanding Print Volume Needs

Another important criterion that defines the selection of an engraving machine is the print volume. Companies that use a lot of print need machines that will be able to produce many plates in a short period without having to sacrifice quality. There are high-speed engraving machines that have better automation to improve the production rates to meet large-scale production. On the other hand, small-scale operations or those that do not print large volumes of paper at a go would find it more appropriate to use machines with a lot of setting options and low cost of operations. However, it is advisable to ensure that the machines acquired are of a size that will not put pressure on the firm in the future because of its ability to produce high volumes of output.

Assessing Plate Size Requirements

Different engraving machines are available in the market. The size of the machine should be chosen to suit the size of the plates to be engraved. It is recommended that businesses determine the maximum plate size that they will be using and compare it with the capabilities of the machine. Thus, for companies that receive a diversified array of plates, it may be beneficial to look for equipment that allows for setting change or component replacement. Also, there is a need to determine the simplicity of putting the machine in place and the ability to adjust it to handle different sizes of plates.

Assessing the Accuracy of the Machine and the Quality

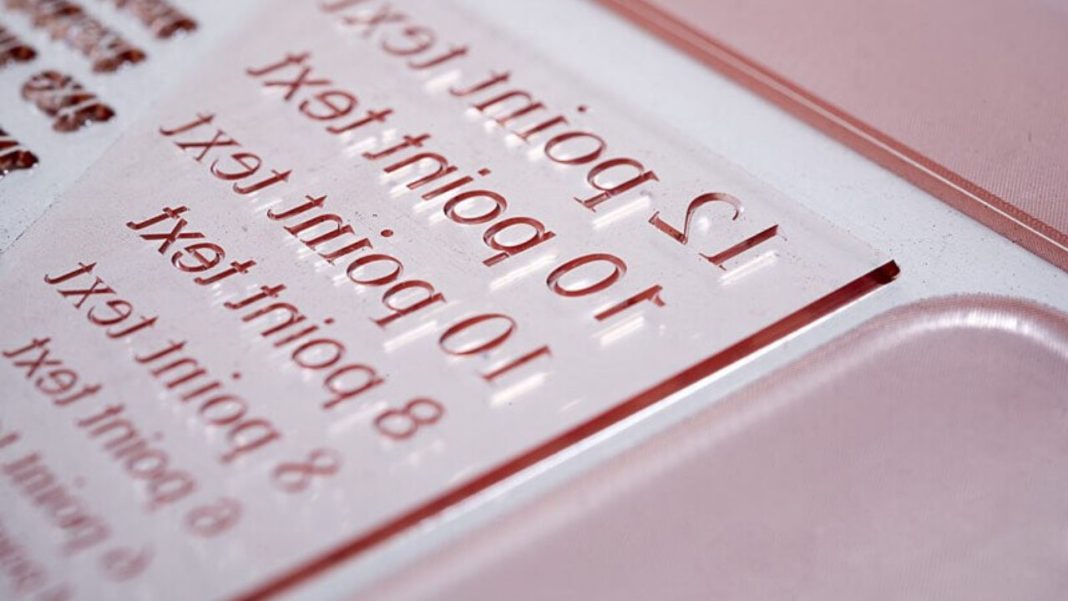

The quality of the engraving machine is very vital in determining the quality of the final prints. Good machines should be able to provide quality engraving that meets the required standards of the print plates. While choosing a machine, it is necessary to pay attention to characteristics like the resolution, the depth of engraving, and the precision of the device that performs the engraving. In this case, it is recommended to search for machines that have additional options such as automatic alignment systems, as well as high-resolution imaging to improve the precision of engraving. Some options pertain to quality control and calibration to ensure that the device performs consistently in the long run.

Considering Maintenance and Support

Companies need to identify the maintenance needs of the prospective machines and go for models that have easy access to spare parts and services. Equipment that is easy to maintain and has detailed assistance services can help reduce the time that an organization’s equipment is out of service and increase the life of the machine. Further, training and technical support from the manufacturer can be helpful in a way that staff can achieve a level of competency in operating and identifying problems with the machine. Selecting machines that have good customer relations and support can go a long way in helping prevent disruptions in the business.

Conclusion

Therefore, when choosing the right engraving machine, one has to consider the size of the plate, the number of prints to be produced, precision, ease of maintenance, and the cost. Thus, by analyzing these aspects, companies can identify the appropriate measures to improve their printing performance and guarantee the quality of the produced documents.